Understanding the Cost of Commercialization for an Alternative Protein Company

Context

As a long time collaborator, Next Rung Technology has been providing process design and scale up support to this specific alternative protein company over an extended period. In this case study, the company raised their first funding round to ramp up production –– the company’s leadership then came to us with the goal of learning how to scale their production from bench scale to their first large scale commercial capacity over three years. In order to clearly understand the economics of their commercialization process, they requested a technoeconomic model mapping out their process alongside the necessary equipment, utilities, and other associated costs.

Process

The Next Rung team conducted a robust technoeconomic analysis to project cost of scale-up and identify key cost-driving levers in the company’s production process.

Process Modeling

The project started by mapping out the company’s existing process and identifying key parameters of interest to be studied with the model, including titer, capacity, and timeline necessary to meet their goals.

An in-depth backend model was developed to represent the company’s process from seed train, production fermentation, to separation and downstream processing (DSP). This model utilized a material balance also developed by the Next Rung team to track all inputs and outputs of the system. Media and water use calculated by the material balance were particularly important in projecting costs associated with wastewater treatment.

Capital Cost Estimation

From the process model and material balance, engineers on the Next Rung team created an appropriately sized and costed equipment list, including cost of installation, labor, and utilities. The equipment list covered major process equipment from bioreactors to filtration skids, as well as supporting systems such as storage tanks, CIP systems, and wastewater treatment systems.

Technoeconomic Analysis

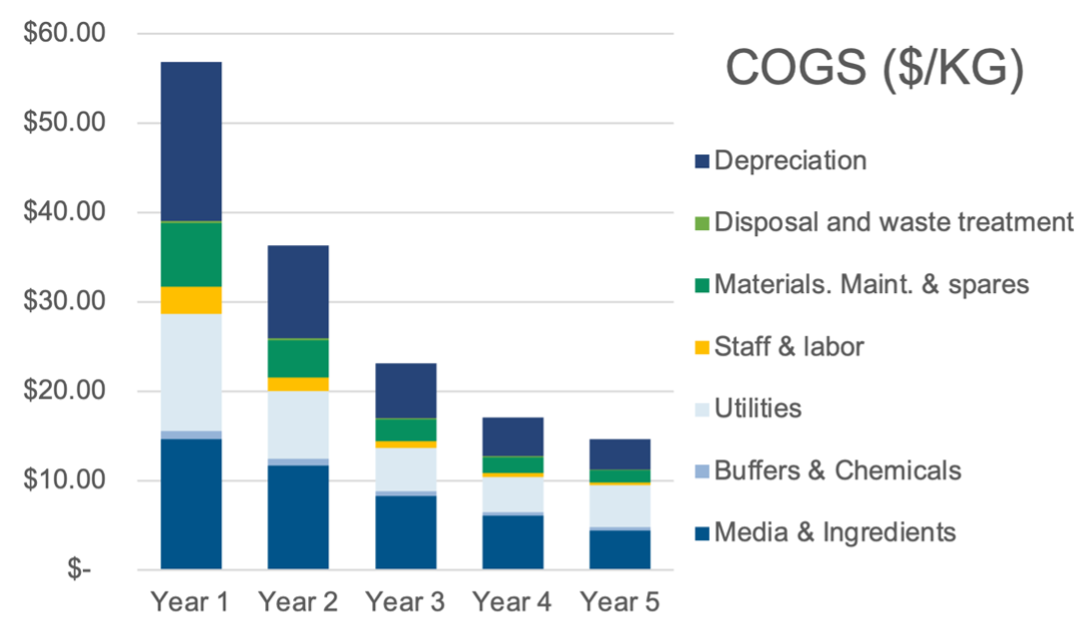

Integrating these detailed aspects in the model allowed Next Rung to provide comprehensive insight into the economics of commercialization for the company. Critical inputs were made available on a live, user-friendly faceplate along with key economic outputs such as cost of goods sold (COGS), target product pricing, and estimated plant revenues. The model calculated the projection of COGS over a five-year ramp-up period, which supported the company’s next round of funding.

Case Studies

After completing the first phase of the TEA, Next Rung worked with the company to conduct extensive case studies to eliminate uncertainty in their R&D process, and develop a process development plan to guide activities for the next several years. The company had eight downstream processes that they were considering for their commercial scale process, but before going into extensive testing in the lab, they leveraged the TEA as a screening tool to identify the most promising options to pursue. By building eight parallel models, Next Rung was able to help compare the processes, identifying hidden expenses or inefficiencies that may have otherwise gone unnoticed until the commercial process was up and running.

Outcomes

The company’s partnership with Next Rung continues — using their technoeconomic model they were able to:

Understand their path to commercialization

Support their next round of funding

Refine their DSP development down to two promising options.

Want to discover how the cost of commercialization can affect your project? Let’s chat!

It’s never too late or too early to start an informed conversation about commercialization costs. Now is always the best time! Fill out the form below to get started.